How Vacuum Cleaners impact your Health With HEPA Filtration

A clean home is often touted as the key to a healthy life,..

Ron@carolinaforestvacuum.com

843-903-6299

7613 SC-544, Myrtle Beach, SC 29588

Carolina Forest Vacuum & Sew is your trusted partner for all vacuum and sewing machine needs, specializing in the sales, repair, and servicing of high-quality vacuums and sewing machines, we pride ourselves on offering exceptional customer service. Whether you need a new machine or repairs on your current one, our expert team is dedicated to ensuring your equipment performs at its best.

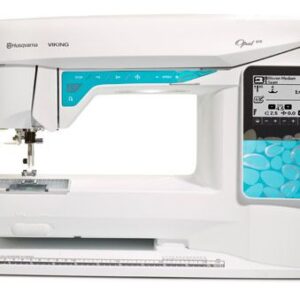

Carolina Forest Vac & Sew offers reliable sewing machines with expert sales and services.

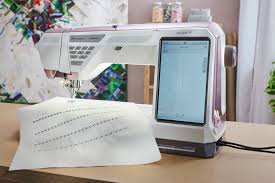

Carolina Forest Vac & Sew offers high-quality embroidery machines for precise stitching and professional results.

Carolina Forest Vac & Sew offers top-quality vacuums and floor care products for effective cleaning and maintenance.

Carolina Forest Vac & Sew provides expert service and repairs for vacuums and sewing machines, ensuring optimal performance.

Best Selling Products

Including top-rated vacuums, sewing machines, and embroidery equipment, trusted for their quality, durability, and performance.

With over 50 years of experience, Carolina Forest Vac & Sew continues to be the go-to name for sewing and vacuum products and services.

We operate locally from Myrtle Beach, SC, offering full support to customers across South Carolina and beyond through our online store.

We handle repairs on all major brands of embroidery machines, vacuums, sewing machines, and floor machines. Estimates are free.

Current Sale Discounts are now live! In-store deals and bonus coupons apply automatically at checkout.

Discover the perfect blend of functionality and performance today.

Create stunning designs effortlessly with our advanced sewing and embroidery machines—precision, speed, and reliability combined

Expert sales and service on all major brands, including Brother, Viking, Singer, Bernina, Juki, Pfaff, Kenmore, Dyson, Shark, and yours.

Multi needle embroidery machine help to eliminate prevent thread changing. Perfect for making embroidery hats in large quantity production.

When it comes to keeping your equipment working the way it should, the right team makes all the difference. That’s why so many locals and online customers choose us for all their vacuum and sewing needs. Whether you’re buying new or bringing in a machine for servicing, we provide clear answers, trusted product lines, and real-time help from a team that knows the ins and outs of these tools.

We understand how much you rely on your machines—at home, in classrooms, or for business. From light home use to professional-grade setups, we support every customer with guidance, repairs, and product recommendations that suit their daily routines. Our hands-on approach helps keep machines running smoothly without guesswork or delays.

High-performance machines built to deliver speed, precision, and lasting results.

Built for durability, our machines handle tough tasks with ease.

Our newest products deliver advanced technology and top-tier user experience

We keep things simple, helpful, and dependable when it comes to your vacuum and sewing machine needs.

At Carolina Forest Vac & Sew, we make it easy to find the support and supplies your machines need.

Our commitment to honest service and lasting solutions keeps customers choosing us time after time.

A visual journey through our top products and real-world applications.

A clean home is often touted as the key to a healthy life,..

What you need to know. Industrial and household sewing machines are designed with..

The Miele Triflex HX2 1182700 Cordless Vacuum offers a versatile cleaning solution that..

Over 405 Built-in embroidery designs and 21 fonts 8" x 8" Maximum embroidery..

Get in touch with our experts and start turning your goals into reality!

7613 Highway 544, Myrtle Beach, SC 29588

Monday–Friday | 9 AM–5 PM (EST)

Unlock Exclusive Updates, Tips, and Offers

Sign Up Now!

Design By Upscalable.co